Inspiration for Trestle Design

Spotlight Solar recently introduced our newest solar stucture product, Trestle, with a stunning 9-unit installation on the grounds of Alliant Energy’s headquarters in Madison Wisconsin. The product rounds out the Spotlight product line with a design that offers the highest capacity and the widest canopy footprint (shade) of any of our solar structure products. It brings a new, stalwart aesthetic to our mix as well. Its lineage is found in the repurposing of old industrial sites into modern mixed-use developments. Often these re-developments have design and construction characteristics that are beautiful in an old-school function-before-form style.

One of these spaces is the American Tobacco Campus in Durham North Carolina, our home town. This historic district is a collection of buildings that emerged from innovations in mass production shortly after the Civil War.

Walking through this huge repurposed industrial space is an archeological journey through the history of functional building materials and techniques. There’s a former coal-burning power plant, a Lucky Strike water tower, a rail car, conveyors, and a whole lotta brick and steel. Nothing is decorative or superficial - beauty is in the way the materials co-exist to hold something up, divide a space, move something from place to place, or simply keep the weather out. But these structures now define and organize modern uses of space and inspire new tenants. In place of big tobacco, there are the big ideas of social entrepreneurs and tech companies; this deliberate contrast has made American Tobacco Campus the thriving hub of the reinvention of Durham. In similar fashion, Trestle provides a compellingly coarse housing to something new and good – clean energy technology.

With that inspiration, we defined these 3 primary design objectives:

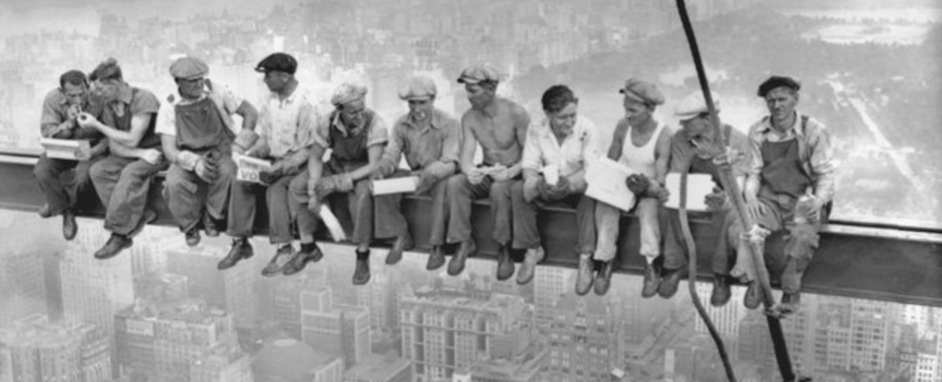

1. Traditional steel shapes. I-beams, L-angles and square tubes. These fundamental building blocks of steel construction are immediately identifiable and infinitely versatile. Remember the iconic photo of workers having lunch atop the Rockefeller Center in 1932? The 11 posing workers connected us to the dizzying heights but the I-beam was the hero.

2. "Too many rivets” was a common refrain as we looked at bridge construction. Today it is typical to minimize and even hide connections. Not for this design. It’s all about the bolts, rivets and welds.

3. Strong. Solid. Beefy. This was not an exercise in minimizing proportions. The wide wingspan required a solid build, so its obvious strength is authentically needed. But since we do experiential solar, it’s also important how the person hanging around under the structure feels. It has to look strong, like the place you want to be during an earthquake.

Trestle embodies these design attributes in all aspects of the solar structure. The massive center mast is a radially arranged group of large tube sections that support each of the three arms. The arms are built with substantial I-beams and are supported underneath with paired L-angles mounted to thick gusset plates. Unique “rivet welds” are used (in the factory) in combination with prodigious bolts (included) to mount the arms. The arrays are supported by a joint design that secures and orients the mounting brackets. These radial and “X” patterns are repeated throughout the assembly.

But despite the rawness of this design, we didn’t forget this is a Spotlight Solar product. Trestle is as much a “beautiful machine” as curve, lift and industry. We painstakingly worked through all the details to make it a pleasure to work with and stand under. The parts arrive finished and ready for assembly, with no cutting, welding or painting required. The thorough assembly guide shows how three people can install it in a day. The arrays have tilt-adjustability during installation to tweak the array up to 10 degrees in two directions. Ground and wire management is clearly laid out, and we even include wire clamps to neatly but visibly run the wire bundle on the top of the arm. Because that’s how it should be.